Sleipner CCS Project (1996)

September 1996 - PresentWhat Happened

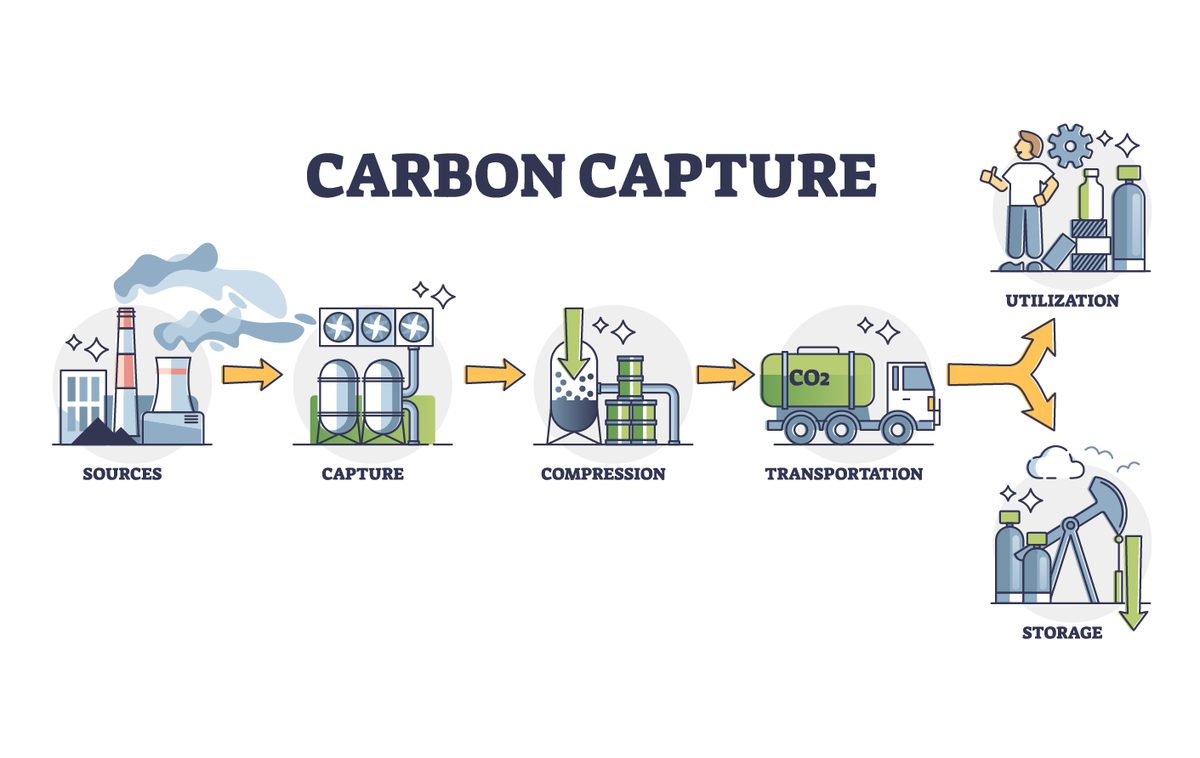

Norway's Sleipner gas field began injecting CO2 separated from natural gas production into a sandstone formation beneath the North Sea. The project was motivated by Norway's 1991 carbon tax, which made storage cheaper than venting. Over 23 million tonnes of CO2 have been stored through a single well.

Outcome

Proved that large-scale CO2 injection into geological formations was technically feasible and that stored CO2 behaved predictably underground.

Became the global reference case for carbon storage, informing regulations and providing the monitoring data that subsequent projects rely upon. However, it also showed that carbon capture remained limited to facilities with concentrated CO2 streams—the dilution problem the KENTECH research addresses.

Why It's Relevant Today

Sleipner demonstrated storage works, but required separating CO2 first. The KENTECH electrode potentially eliminates that separation step, addressing the economic barrier that has limited capture technology deployment for three decades.